ECOCOOL

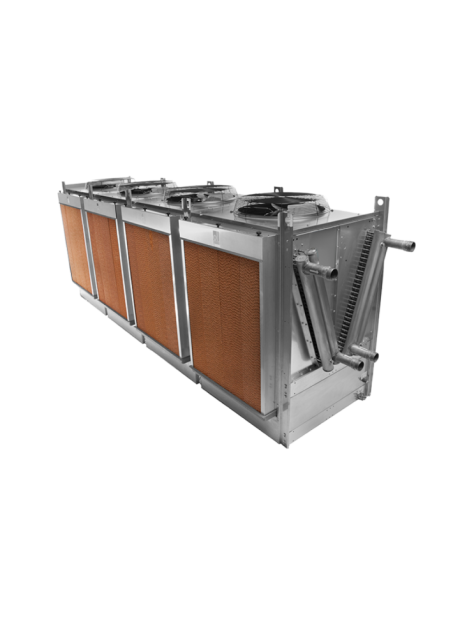

This new MODULAR system for cooling water from industrial processes is the most innovative and innovative to obtain the MAXIMUM ECONOMY in the cooling of oleodynamic circuit process waters, condensed water chillers, water cooling for the smelters, aluminum injection, food industries, chemical industries or for any industrial process where water cooling is required at room temperature.

The new technology implemented in the construction of the Dry Cooler, combined with an optimal control device, results in an extremely reliable work cycle and allows to reach a temperature of water coming out of the Dry Coolers with values very close to the intake air temperature , even when the ambient temperature is very close to the temperature of the water to cool.

Another convenience of using ECOCOOL SYSTEM is that temperatures below zero graphs antifreeze can be added to the circulating liquid in the plant

In addition, this plant has a self-draining system and is equipped with high efficiency fans. Also, in the construction of the exchanger, low-thickness copper pipe coated with aluminum fins is used, which gives the ECOCOOL SYSTEM a better performance

Thanks to the use of high-efficiency radiators in pure copper, ANDELY Dry Coolers (ECOCOOL SYSTEM) can guarantee a constant temperature + 2/3 ° C above room temperature WITHOUT the use of water mist systems or adiabatic panels. In addition, the ECOCOOL SYSTEM is able to cool 2 separate circuits using the same cooler, which means less occupied space and lower operating costs.